This section covers aspects of: • the 400 year-old industry that exploits deposits of high quality clay in the Bovey Basin; • the Stover Canal, which opened in 1790 for barges to transport clay from the quarries to the head of the Teign estuary; • the Haytor granite quarries and the tramway linking to the canal; • coal deposits in the Bovey Basin; • interesting finds in the Zitherixon quarry; and • the town of Kingsteignton, situated between the Bovey Basin and the head of the estuary.  Fore Street, Kingsteignton (February 2012). The retained shop frontage in this terraced property is an attractive feature in a street otherwise dominated by double yellow lines. There are now no shops open in the old town centre, all the trade having been sucked away by ‘superstores’ or out-of-town retail parks. Ball Clay The section of the Teign valley between Bovey Tracey and Newton Abbot, known as the Bovey Basin, took many thousands of years to fill with sediment from the Teign and the Bovey. The sediment included clay derived from decomposed granite, which is purer and more refined than many others and has been used in several different types of product, particularly in ceramic wares.

Fore Street, Kingsteignton (February 2012). The retained shop frontage in this terraced property is an attractive feature in a street otherwise dominated by double yellow lines. There are now no shops open in the old town centre, all the trade having been sucked away by ‘superstores’ or out-of-town retail parks. Ball Clay The section of the Teign valley between Bovey Tracey and Newton Abbot, known as the Bovey Basin, took many thousands of years to fill with sediment from the Teign and the Bovey. The sediment included clay derived from decomposed granite, which is purer and more refined than many others and has been used in several different types of product, particularly in ceramic wares.  The clay pits and surface waste around Teigngrace are very visible in the landscape looking north from Highweek churchyard. (September 2012) When clay was first exploited commercially in the 1600s it was extracted from close to the surface by simply digging it out in courses using specially shaped spades, similar to peat cutting – the resulting square lumps were called ‘balls’ presumably because the corners became rounded when they were moved – hence the term ‘ball clay’. Originally, packhorses carried the clay on a slow seven or eight mile journey from the pits to the nearest port at Teignmouth. This journey was shortened when storage buildings (known as cellars) were built at Hackney quay at the head of the Teign estuary, where the clay was either loaded directly into small coastal sailing vessels or taken down the estuary by barge to larger sailing vessels moored in Teignmouth harbour. The first recorded shipment from Teignmouth was to Plymouth in 1691. The white firing properties of the clay attracted interest from potters looking for materials to improve their wares, and the potential for the local industry was boosted in 1791 when Josiah Wedgwood first purchased clay from the Bovey Basin. This prompted James Templer, a big local landowner, to invest in a canal to move the clay from the pits area to Jetty Marsh in Newton Abbot and then onward by barge to Teignmouth. The river was dredged near the entrance to the canal so that barges could load to a greater draught than before. From 1795 a small fleet of barges transported clay from the canal loading points to Teignmouth harbour, ten operating regularly on the river, of which Templer himself owned eight, each able to carry about 30 tons.

The clay pits and surface waste around Teigngrace are very visible in the landscape looking north from Highweek churchyard. (September 2012) When clay was first exploited commercially in the 1600s it was extracted from close to the surface by simply digging it out in courses using specially shaped spades, similar to peat cutting – the resulting square lumps were called ‘balls’ presumably because the corners became rounded when they were moved – hence the term ‘ball clay’. Originally, packhorses carried the clay on a slow seven or eight mile journey from the pits to the nearest port at Teignmouth. This journey was shortened when storage buildings (known as cellars) were built at Hackney quay at the head of the Teign estuary, where the clay was either loaded directly into small coastal sailing vessels or taken down the estuary by barge to larger sailing vessels moored in Teignmouth harbour. The first recorded shipment from Teignmouth was to Plymouth in 1691. The white firing properties of the clay attracted interest from potters looking for materials to improve their wares, and the potential for the local industry was boosted in 1791 when Josiah Wedgwood first purchased clay from the Bovey Basin. This prompted James Templer, a big local landowner, to invest in a canal to move the clay from the pits area to Jetty Marsh in Newton Abbot and then onward by barge to Teignmouth. The river was dredged near the entrance to the canal so that barges could load to a greater draught than before. From 1795 a small fleet of barges transported clay from the canal loading points to Teignmouth harbour, ten operating regularly on the river, of which Templer himself owned eight, each able to carry about 30 tons.  A direction sign for the Templer Way footpath on the bridge over the canal at Wharf Road Sidings (September 2009) Extracting the clay As noted above, when ball clay was first exploited commercially, material found close to the surface was extracted manually using specially shaped hand tools to cut 9 inch cubes of clay from shallow trenches. In the 19th century improved pumping techniques enabled quarrying from larger open pits with terraced sides, and later underground shafts were used to reach deeper clay deposits up to 200 feet down. The miners worked underground by candlelight and sometimes ankle deep in water, in cramped shafts that typically were only 5 ½ feet high and 4 feet wide. Clay would squeeze through the timber supports, and each shaft seldom lasted more than two years. The heavy clay was manhandled onto wheelbarrows for moving to the surface. There was the ever-present threat of a sudden water inrush and the ignition of ‘fire damp’ methane gases. Records of serious accidents are surprisingly rare, but in these conditions injuries and ill health must have been common among the miners. In the early 1900′s steam generated DC electricity was introduced and rail-mounted wagons hauled by wire ropes were used to transport the clay to the surface, but otherwise little mechanisation was introduced until after the Second World War, after which mechanical excavators, dumpers and pneumatic spaders came into general use to relieve the workers of the hardest physical labour, together with draglines to allow the removal of greater thicknesses of overburden. ‘Adit’ or ‘inclined tunnel’ mining came into use in the1930s, to follow seams from the bottom of existing pits, and was still employed until the 1990s. During the 1960′s the adit system was greatly improved with the introduction of hydraulic mining machines, submersible pumps and wagons with automatic tipping at the surface. The longest adit drives extended underground for over half a mile to a depth of up to 450ft , and some had 25 year productive lives. Underground mining was relatively expensive due to high labour costs, the need for large quantities of timber for tunnel supports, and the costs involved in stringent safety measures. As the mechanisation of opencast working progressed, underground mining became increasingly uneconomic, except to extract seams of the highest value that lay too deep for opencast workings to reach. In the Bovey Basin the last underground mine was closed in 1999. Now all production is from progressively larger and deeper open pits using powerful hydraulic excavators and dumpers.

A direction sign for the Templer Way footpath on the bridge over the canal at Wharf Road Sidings (September 2009) Extracting the clay As noted above, when ball clay was first exploited commercially, material found close to the surface was extracted manually using specially shaped hand tools to cut 9 inch cubes of clay from shallow trenches. In the 19th century improved pumping techniques enabled quarrying from larger open pits with terraced sides, and later underground shafts were used to reach deeper clay deposits up to 200 feet down. The miners worked underground by candlelight and sometimes ankle deep in water, in cramped shafts that typically were only 5 ½ feet high and 4 feet wide. Clay would squeeze through the timber supports, and each shaft seldom lasted more than two years. The heavy clay was manhandled onto wheelbarrows for moving to the surface. There was the ever-present threat of a sudden water inrush and the ignition of ‘fire damp’ methane gases. Records of serious accidents are surprisingly rare, but in these conditions injuries and ill health must have been common among the miners. In the early 1900′s steam generated DC electricity was introduced and rail-mounted wagons hauled by wire ropes were used to transport the clay to the surface, but otherwise little mechanisation was introduced until after the Second World War, after which mechanical excavators, dumpers and pneumatic spaders came into general use to relieve the workers of the hardest physical labour, together with draglines to allow the removal of greater thicknesses of overburden. ‘Adit’ or ‘inclined tunnel’ mining came into use in the1930s, to follow seams from the bottom of existing pits, and was still employed until the 1990s. During the 1960′s the adit system was greatly improved with the introduction of hydraulic mining machines, submersible pumps and wagons with automatic tipping at the surface. The longest adit drives extended underground for over half a mile to a depth of up to 450ft , and some had 25 year productive lives. Underground mining was relatively expensive due to high labour costs, the need for large quantities of timber for tunnel supports, and the costs involved in stringent safety measures. As the mechanisation of opencast working progressed, underground mining became increasingly uneconomic, except to extract seams of the highest value that lay too deep for opencast workings to reach. In the Bovey Basin the last underground mine was closed in 1999. Now all production is from progressively larger and deeper open pits using powerful hydraulic excavators and dumpers.  The ball clay quarry at New Bridge, Heathfield (January 2010, © Robin Stott) Uses for the clay Traditionally, ball clays were sold ‘as dug’ in lumps or ‘balls’ – the ‘potters” clays usually being weathered for several months in outside heaps. Each ‘ball’ weighed about 36 lbs (16 kilos) and were loaded onto carts using a pole with a metal spit on the end, called a ‘poge’. The clay producers did some very crude selection and mixing of what they perceived to be good and bad examples of individual clay types. The potters often bought in a variety of clays and mixed them together to their ‘secret’ formulae to make the pottery body they wanted. This procedure continued virtually unchanged until the widespread adoption in the 1950′s of the ‘shredding’ of clay into small pieces. This makes handling much easier and enables the clay producers to blend together material from different seams of clay, often from different production areas, to meet the users’ specification. Also, the development of powdering facilitated the sale of ball clays into non-ceramic applications such as rubber, fertilisers and animal feeds. The powder is produced by feeding shredded clay into a rotating mill which breaks it down into smaller particles and dries the clay from its natural 15-18% moisture content down to 2%. The end product is then filtered and either bagged in paper sacks or delivered in bulk powder tankers. Currently, about 75% of ball clay production is sold in shredded and blended form, 10% in powdered form and 15% is refined. Less than 1% is sold ‘as dug’. As with other types of mineral extraction, large quantities of waste are produced, in this case from the quarrying of the material on top of (the ‘overburden’)and between the seams of the ball clay (the ‘interburden’). It is difficult to imagine the Bovey Basin area ever reverting to anything like its natural state before the quarrying started.

The ball clay quarry at New Bridge, Heathfield (January 2010, © Robin Stott) Uses for the clay Traditionally, ball clays were sold ‘as dug’ in lumps or ‘balls’ – the ‘potters” clays usually being weathered for several months in outside heaps. Each ‘ball’ weighed about 36 lbs (16 kilos) and were loaded onto carts using a pole with a metal spit on the end, called a ‘poge’. The clay producers did some very crude selection and mixing of what they perceived to be good and bad examples of individual clay types. The potters often bought in a variety of clays and mixed them together to their ‘secret’ formulae to make the pottery body they wanted. This procedure continued virtually unchanged until the widespread adoption in the 1950′s of the ‘shredding’ of clay into small pieces. This makes handling much easier and enables the clay producers to blend together material from different seams of clay, often from different production areas, to meet the users’ specification. Also, the development of powdering facilitated the sale of ball clays into non-ceramic applications such as rubber, fertilisers and animal feeds. The powder is produced by feeding shredded clay into a rotating mill which breaks it down into smaller particles and dries the clay from its natural 15-18% moisture content down to 2%. The end product is then filtered and either bagged in paper sacks or delivered in bulk powder tankers. Currently, about 75% of ball clay production is sold in shredded and blended form, 10% in powdered form and 15% is refined. Less than 1% is sold ‘as dug’. As with other types of mineral extraction, large quantities of waste are produced, in this case from the quarrying of the material on top of (the ‘overburden’)and between the seams of the ball clay (the ‘interburden’). It is difficult to imagine the Bovey Basin area ever reverting to anything like its natural state before the quarrying started.  Clay waste at Stover Quarry (February 2010, © Robin Stott) The majority of ball clay is used in the ceramics industry, mainly for the manufacture of sanitaryware, tiles and tableware. It is also used in refractories, in the production of pharmaceuticals and fertilisers, and is sometimes employed as a filler for rubber and plastic products such as windscreen wipers and garden hoses. Ball clay derives its value from its high plasticity, fine grained nature and strength when dry, and the fact that when fired it has a light colour. Devon’s ball clay reserves are of national and international importance due to the rarity of the mineral in England and Europe as a whole. Its three predominant components are kaolinite, mica and quartz, but it is highly variable in composition, and it is often necessary to blend clays from different quarries to meet customers’ specifications.

Clay waste at Stover Quarry (February 2010, © Robin Stott) The majority of ball clay is used in the ceramics industry, mainly for the manufacture of sanitaryware, tiles and tableware. It is also used in refractories, in the production of pharmaceuticals and fertilisers, and is sometimes employed as a filler for rubber and plastic products such as windscreen wipers and garden hoses. Ball clay derives its value from its high plasticity, fine grained nature and strength when dry, and the fact that when fired it has a light colour. Devon’s ball clay reserves are of national and international importance due to the rarity of the mineral in England and Europe as a whole. Its three predominant components are kaolinite, mica and quartz, but it is highly variable in composition, and it is often necessary to blend clays from different quarries to meet customers’ specifications.  A bulk tanker at the entrance to Teignmouth harbour (May 2009) The export of the high grade clay, together with granite and limestone, has been largely responsible for the development of Teignmouth Docks. Over 80% is exported, mainly to Italy and Spain, though some is still transported to the remaining ceramics businesses in the English Potteries area. In 2001 the Bovey Basin had estimated permitted reserves of ball clay of 63 million tonnes, enough for about another 100 years of extraction at current rates. The presence of ball clay is a result of the Sticklepath Fault, which occurred around 30 million years ago during the Tertiary period. This runs north-west to south-east across Devon from Bideford Bay to Torbay, and created subsidence which enabled the accumulation of clays and sands which form the ball clay deposits. Ball clays are often confused with china clays. Ball clays consist of ultra fine clay particles, which helps to make them sticky (or ‘plastic’) and easily shaped when damp. Some also have fluid properties that are valuable in the casting of large ceramic pieces such as toilet bowls. Both china clays and English ball clays contain a large proportion of the mineral kaolinite and fire hard in the potter’s kiln. However, china clay particles are much coarser. Consequently, china clays are not generally plastic. Most types of ‘whiteware’ pottery contain both ball clay and china clay. The ball clay helps to shape the piece, adding ‘green’ strength to the body before firing, whilst china clay provides extra whiteness. In the mid 19th century the pottery at Bovey employed 300 people, some of whom had originally learnt their trade in the Staffordshire potteries. It made a wide range of goods including dinner services; jugs, basins, teapots and cups, bowls and bed pans. The pottery closed in 1956. Today the bottle kilns and examples of local pottery can be seen at the museum located at the House of Marbles, to the south of the town.

A bulk tanker at the entrance to Teignmouth harbour (May 2009) The export of the high grade clay, together with granite and limestone, has been largely responsible for the development of Teignmouth Docks. Over 80% is exported, mainly to Italy and Spain, though some is still transported to the remaining ceramics businesses in the English Potteries area. In 2001 the Bovey Basin had estimated permitted reserves of ball clay of 63 million tonnes, enough for about another 100 years of extraction at current rates. The presence of ball clay is a result of the Sticklepath Fault, which occurred around 30 million years ago during the Tertiary period. This runs north-west to south-east across Devon from Bideford Bay to Torbay, and created subsidence which enabled the accumulation of clays and sands which form the ball clay deposits. Ball clays are often confused with china clays. Ball clays consist of ultra fine clay particles, which helps to make them sticky (or ‘plastic’) and easily shaped when damp. Some also have fluid properties that are valuable in the casting of large ceramic pieces such as toilet bowls. Both china clays and English ball clays contain a large proportion of the mineral kaolinite and fire hard in the potter’s kiln. However, china clay particles are much coarser. Consequently, china clays are not generally plastic. Most types of ‘whiteware’ pottery contain both ball clay and china clay. The ball clay helps to shape the piece, adding ‘green’ strength to the body before firing, whilst china clay provides extra whiteness. In the mid 19th century the pottery at Bovey employed 300 people, some of whom had originally learnt their trade in the Staffordshire potteries. It made a wide range of goods including dinner services; jugs, basins, teapots and cups, bowls and bed pans. The pottery closed in 1956. Today the bottle kilns and examples of local pottery can be seen at the museum located at the House of Marbles, to the south of the town.  A decorative Dartmoor Ware mug produced by the Bovey Pottery, probably in the 1950s. Until the mid 18th century Heathfield was almost a swamp, containing a vast extent of decayed vegetation and some animal matter, about which the Will o’ the Wisp (a ghostly light sometimes seen over marshes and bogs) used to flit in the autumn. Drainage associated with the construction of the Stover Canal helped to improve living conditions – eliminating the leeches and the ague that used to affect those living in the valley. Much of this area is now the site of an industrial estate.

A decorative Dartmoor Ware mug produced by the Bovey Pottery, probably in the 1950s. Until the mid 18th century Heathfield was almost a swamp, containing a vast extent of decayed vegetation and some animal matter, about which the Will o’ the Wisp (a ghostly light sometimes seen over marshes and bogs) used to flit in the autumn. Drainage associated with the construction of the Stover Canal helped to improve living conditions – eliminating the leeches and the ague that used to affect those living in the valley. Much of this area is now the site of an industrial estate.

The Stover Canal

The Stover Canal, a bit less than two miles long and built entirely on Templer’s own land, shortened the overland part of this journey considerably and by 1816 trade on the Teign had increased from 400 boatloads of clay per year before the canal was built, to 600 per year, and by 1854 this had increased to 1,000 per year.

The footpath along the canal between Teigngrace and Teign Bridge: part of the Templer Way (March 2012).

The footpath along the canal between Teigngrace and Teign Bridge: part of the Templer Way (March 2012).

One might have expected that the barges were pulled by horses, but a recent (2017) communication from John Ellis, researcher for the Stover Canal Trust, said ‘… no records have been found of any mention of horses or ponies in use on the canal. The barges were either bow-hauled or poled down by men, or sailed on the canal using their unique Viking rig sail. The stables alongside the canal, now the scrapyard, were used to house the horses and ponies used to pull the carts bringing the clay to the cellars at Teignbridge.’

”  The remains of the Stover Canal lock at Teigngrace. (March 2012) A small building supplies company operates (somewhat precariously) from a strip of land on the left bank of the lock. In 2014 an archaeological team working at Ventiford Basin uncovered the remains of one of the timber barges that used to be deployed on the canal. The team were also interested in the different cargoes that were carried, and found evidence for coal and flint cobbles being transported inland from the coast, probably for use in the local ceramics industry. They also found some micaceous haematite, known as ‘shiny ore’, because it sparkles with flakes of iron oxide, which was mined in several places in the Wray Valley. The ore was used in the glazing process at the local potteries, and later became important as a base for corrosion-resistant paint. The canal was fed from different points from Ventiford Brook, the River Bovey and the River Teign, and flowed out into the tidal Whitelake Channel and from there into the Teign estuary. The Teigngrace lock was the first after the start of the canal at Ventiford, and the next was the so-called Graving Dock lock.

The remains of the Stover Canal lock at Teigngrace. (March 2012) A small building supplies company operates (somewhat precariously) from a strip of land on the left bank of the lock. In 2014 an archaeological team working at Ventiford Basin uncovered the remains of one of the timber barges that used to be deployed on the canal. The team were also interested in the different cargoes that were carried, and found evidence for coal and flint cobbles being transported inland from the coast, probably for use in the local ceramics industry. They also found some micaceous haematite, known as ‘shiny ore’, because it sparkles with flakes of iron oxide, which was mined in several places in the Wray Valley. The ore was used in the glazing process at the local potteries, and later became important as a base for corrosion-resistant paint. The canal was fed from different points from Ventiford Brook, the River Bovey and the River Teign, and flowed out into the tidal Whitelake Channel and from there into the Teign estuary. The Teigngrace lock was the first after the start of the canal at Ventiford, and the next was the so-called Graving Dock lock.  Remains of the Graving Dock lock (March 2012). The walls are made from large granite blocks from the Haytor quarries. This site is in the process of being reclaimed after decades of neglect, by the Stover Canal Society. It was constructed with a small basin at the side of the lock, the wall of which is seen at the top left of the photo, and again below. This basin could be used as a dry dock when the lock was empty – a barge could be hauled up onto the ledge for inspection and repair. (A graving dock is an alternative name for a dry dock, and the term ‘graving’ actually means ‘scratching’ ¬ sea-going vessels needed barnacles and rust scratched off their hulls.)

Remains of the Graving Dock lock (March 2012). The walls are made from large granite blocks from the Haytor quarries. This site is in the process of being reclaimed after decades of neglect, by the Stover Canal Society. It was constructed with a small basin at the side of the lock, the wall of which is seen at the top left of the photo, and again below. This basin could be used as a dry dock when the lock was empty – a barge could be hauled up onto the ledge for inspection and repair. (A graving dock is an alternative name for a dry dock, and the term ‘graving’ actually means ‘scratching’ ¬ sea-going vessels needed barnacles and rust scratched off their hulls.)  The basin at Graving Dock (March 2012) At one time James Templer intended to extend the canal to Bovey Tracey, with a branch being cut towards Chudleigh. To enable him to raise money to finance this scheme he commissioned a Private Bill which was passed as an Act of Parliament on 11th June 1792. But implementation would have involved mortgaging the whole of his Stover Estate, and he didn’t proceed, presumably because he didn’t want to risk everything on one venture. On a part of his vast estate of 80,000 acres he had built himself a mansion in the Palladian style, called Stover House. The gardens were the subject of a major landscaping scheme, which included planting 200,000 trees and creating the 10 acre lake that now forms the centrepiece of Stover Country Park. The park is a Site of Special Scientific Interest, run by Devon County Council. The house is now occupied by Stover School.

The basin at Graving Dock (March 2012) At one time James Templer intended to extend the canal to Bovey Tracey, with a branch being cut towards Chudleigh. To enable him to raise money to finance this scheme he commissioned a Private Bill which was passed as an Act of Parliament on 11th June 1792. But implementation would have involved mortgaging the whole of his Stover Estate, and he didn’t proceed, presumably because he didn’t want to risk everything on one venture. On a part of his vast estate of 80,000 acres he had built himself a mansion in the Palladian style, called Stover House. The gardens were the subject of a major landscaping scheme, which included planting 200,000 trees and creating the 10 acre lake that now forms the centrepiece of Stover Country Park. The park is a Site of Special Scientific Interest, run by Devon County Council. The house is now occupied by Stover School.  Stover Country Park lake (August 2013) James Templer’s grandson George inherited the estate in 1813. He was responsible for the construction of the granite tramway, but preferred to indulge his interests in amateur dramatics, music and poetry. He even brought in an All England cricket team to play Teignbridge village team, the first permanent cricket club in Devon, in Stover Park By 1829 he was almost broke and sold his whole estate, including the canal, to Edward Seymour, Duke of Somerset.

Stover Country Park lake (August 2013) James Templer’s grandson George inherited the estate in 1813. He was responsible for the construction of the granite tramway, but preferred to indulge his interests in amateur dramatics, music and poetry. He even brought in an All England cricket team to play Teignbridge village team, the first permanent cricket club in Devon, in Stover Park By 1829 he was almost broke and sold his whole estate, including the canal, to Edward Seymour, Duke of Somerset.  The ‘aerial walkway’ through mature trees by the side of Stover Park lake (August 2013) But to get back to the main subject of this section …the Stover Canal ran more or less parallel to the Teign. About 300m down the road from Teign Bridge the road crosses the course of the canal, now completely overgrown – see below. A small section of the canal wall with projecting girders, which presumably used to support a loading platform or chutes, can be seen on the right.

The ‘aerial walkway’ through mature trees by the side of Stover Park lake (August 2013) But to get back to the main subject of this section …the Stover Canal ran more or less parallel to the Teign. About 300m down the road from Teign Bridge the road crosses the course of the canal, now completely overgrown – see below. A small section of the canal wall with projecting girders, which presumably used to support a loading platform or chutes, can be seen on the right.  (May 2009) A photograph taken from the same bridge in the mid-1930s shows a worker’s cottage and a line of sheds stretching for about 50m along the left bank of the canal – the chimney of the cottage is just visible.

(May 2009) A photograph taken from the same bridge in the mid-1930s shows a worker’s cottage and a line of sheds stretching for about 50m along the left bank of the canal – the chimney of the cottage is just visible.  Remaining section of the Stover Canal (September 2009). This is the Whitelake Channel, just downstream from Kingsteignton Bridge, with the railway bridge of the Moretonhampstead branch line is in the background. The footpath here is part of the Templer Way. This was originally a natural drainage channel, deepened to form the entry to the canal Up until the 1950s sand barges unloaded at what is now the B&Q car park. When the canal was in operation men would use the path to haul the barges by a rope attached to the bow. (The barges also had sails but I imagine along the canal they would only have been effective if the wind was blowing close to the right direction.)

Remaining section of the Stover Canal (September 2009). This is the Whitelake Channel, just downstream from Kingsteignton Bridge, with the railway bridge of the Moretonhampstead branch line is in the background. The footpath here is part of the Templer Way. This was originally a natural drainage channel, deepened to form the entry to the canal Up until the 1950s sand barges unloaded at what is now the B&Q car park. When the canal was in operation men would use the path to haul the barges by a rope attached to the bow. (The barges also had sails but I imagine along the canal they would only have been effective if the wind was blowing close to the right direction.)  Another view of the Whitelake Channel, with an unsightly scrap yard on the opposite bank only partly hidden by vegetation. (May 2009)

Another view of the Whitelake Channel, with an unsightly scrap yard on the opposite bank only partly hidden by vegetation. (May 2009)  A view of the same scrap yard taken from Knowles Hill. (February 2012) I suppose scrap yards have to be somewhere, but why so close to the river? – it appears that vehicles are dismantled on the site – there must be a risk of pollution. In August 2013 the first phase was completed of the project to make the canal footpath accessible to the public, with the opening of the section between Teign Lock and Jetty Marsh. Granite From 1820 the canal was also used in conjunction with George Templer’s tramway, for moving granite from the family’s quarry on Haytor Down, to Ventiford at the head of the canal. The flanged rails were cut from the same granite they were designed to transport.

A view of the same scrap yard taken from Knowles Hill. (February 2012) I suppose scrap yards have to be somewhere, but why so close to the river? – it appears that vehicles are dismantled on the site – there must be a risk of pollution. In August 2013 the first phase was completed of the project to make the canal footpath accessible to the public, with the opening of the section between Teign Lock and Jetty Marsh. Granite From 1820 the canal was also used in conjunction with George Templer’s tramway, for moving granite from the family’s quarry on Haytor Down, to Ventiford at the head of the canal. The flanged rails were cut from the same granite they were designed to transport.  A tramway rail set upright in the ground at Parke (August 2013). Several of these rails are set up in a line across the meadows – two more can just be seen in the background. The opening of the tramway was celebrated in some style: the Flying Post recorded that there was a procession including a long string of carriages filled with elegant and beautiful women, multitudes of horsemen, workmen on foot, the wagons all covered with laurels and waving streamers. The tramway descended more than 1,300 feet over a distance of seven miles. The wagons were arranged in trains of about twelve.

A tramway rail set upright in the ground at Parke (August 2013). Several of these rails are set up in a line across the meadows – two more can just be seen in the background. The opening of the tramway was celebrated in some style: the Flying Post recorded that there was a procession including a long string of carriages filled with elegant and beautiful women, multitudes of horsemen, workmen on foot, the wagons all covered with laurels and waving streamers. The tramway descended more than 1,300 feet over a distance of seven miles. The wagons were arranged in trains of about twelve.  A wagon similar to that used on the Haytor tramway. This one was found abandoned at Combeinteignhead; its wheels are slightly too small to have been used on the Haytor tramway, but it must have been used on something similar. It is on display in a shed behind Parke House (August 2013). Going downhill braking was by means of a pole applied to the rim of the wheel and/or horses tethered to the back. It’s amazing that this worked – it must have needed some really tough, skilful men to get the wagons down to the bottom without mishap.

A wagon similar to that used on the Haytor tramway. This one was found abandoned at Combeinteignhead; its wheels are slightly too small to have been used on the Haytor tramway, but it must have been used on something similar. It is on display in a shed behind Parke House (August 2013). Going downhill braking was by means of a pole applied to the rim of the wheel and/or horses tethered to the back. It’s amazing that this worked – it must have needed some really tough, skilful men to get the wagons down to the bottom without mishap.  A section of the granite tramway uncovered recently at Ventiford Basin (October 2016) Haytor quarries were being used to supply stone for major works like the London Bridge (the one sold to an American oil tycoon in 1968, taken apart and shipped in pieces for re-assembly in Arizona). In 1850 the quarries employed one hundred men but the granite trade was sporadic, with Haytor finding it increasingly difficult to compete with the more economic Cornish coastal quarries, and both the quarries and tramway closed in 1858. The Templer Way footpath runs for 18 miles between Haytor and Teignmouth, and traces the route by which granite was exported via the Haytor Granite Tramway and the Stover Canal.

A section of the granite tramway uncovered recently at Ventiford Basin (October 2016) Haytor quarries were being used to supply stone for major works like the London Bridge (the one sold to an American oil tycoon in 1968, taken apart and shipped in pieces for re-assembly in Arizona). In 1850 the quarries employed one hundred men but the granite trade was sporadic, with Haytor finding it increasingly difficult to compete with the more economic Cornish coastal quarries, and both the quarries and tramway closed in 1858. The Templer Way footpath runs for 18 miles between Haytor and Teignmouth, and traces the route by which granite was exported via the Haytor Granite Tramway and the Stover Canal.  A stone plaque marking the footpath route at the Town Quay, with the new suspension bridge in the background, which provides a walking and cycling link to Kingsteignton (October 2013) The Moretonhampstead railway In 1858 the Moretonhampstead and South Devon Railway Company (MSDR) was formed with the aim of constructing a line from Newton Abbot Station to Moretonhampstead. The course of the railway meant that it had to pass through the Duke of Somerset’s land. He realised it was an opportunity to offload the canal, which had not produced the revenues he had expected, and as an inducement he could offer a section of the old tramway from Ventiford to form the part of the route of the railway. Negotiations for the sale of land commenced in 1861 and were completed by June 1862 in a deed which sold the Stover Canal to the railway company. The new railway, completed in 1866, ran from Newton station alongside the canal to Ventiford and from there over the course of the old tramway to Brimley. By now the section of the canal above Teignbridge was little used apart from giving barges access to the new Graving Dock Lock, which had become the main barge repair yard.

A stone plaque marking the footpath route at the Town Quay, with the new suspension bridge in the background, which provides a walking and cycling link to Kingsteignton (October 2013) The Moretonhampstead railway In 1858 the Moretonhampstead and South Devon Railway Company (MSDR) was formed with the aim of constructing a line from Newton Abbot Station to Moretonhampstead. The course of the railway meant that it had to pass through the Duke of Somerset’s land. He realised it was an opportunity to offload the canal, which had not produced the revenues he had expected, and as an inducement he could offer a section of the old tramway from Ventiford to form the part of the route of the railway. Negotiations for the sale of land commenced in 1861 and were completed by June 1862 in a deed which sold the Stover Canal to the railway company. The new railway, completed in 1866, ran from Newton station alongside the canal to Ventiford and from there over the course of the old tramway to Brimley. By now the section of the canal above Teignbridge was little used apart from giving barges access to the new Graving Dock Lock, which had become the main barge repair yard.  A remaining section of the Newton Abbot to Heathfield line at Teigngrace (March 2012) The ownership of the canal changed again in 1872 when the MSDR was absorbed by the South Devon Railway, which in turn became part of the Great Western Railway following a merger in 1877. Meanwhile the number of barge journeys along the Teign Estuary continued to grow, reaching approximately 2,500 per annum by 1900. But then from the 1920s road transport gradually took over, and the advent of powerful, more reliable diesel-powered lorries in the 1930s led to the canal’s closure in 1939, and it was abandoned. Twelve years later the canal burst its banks, with flood water spilling over into the East Golds clay works.

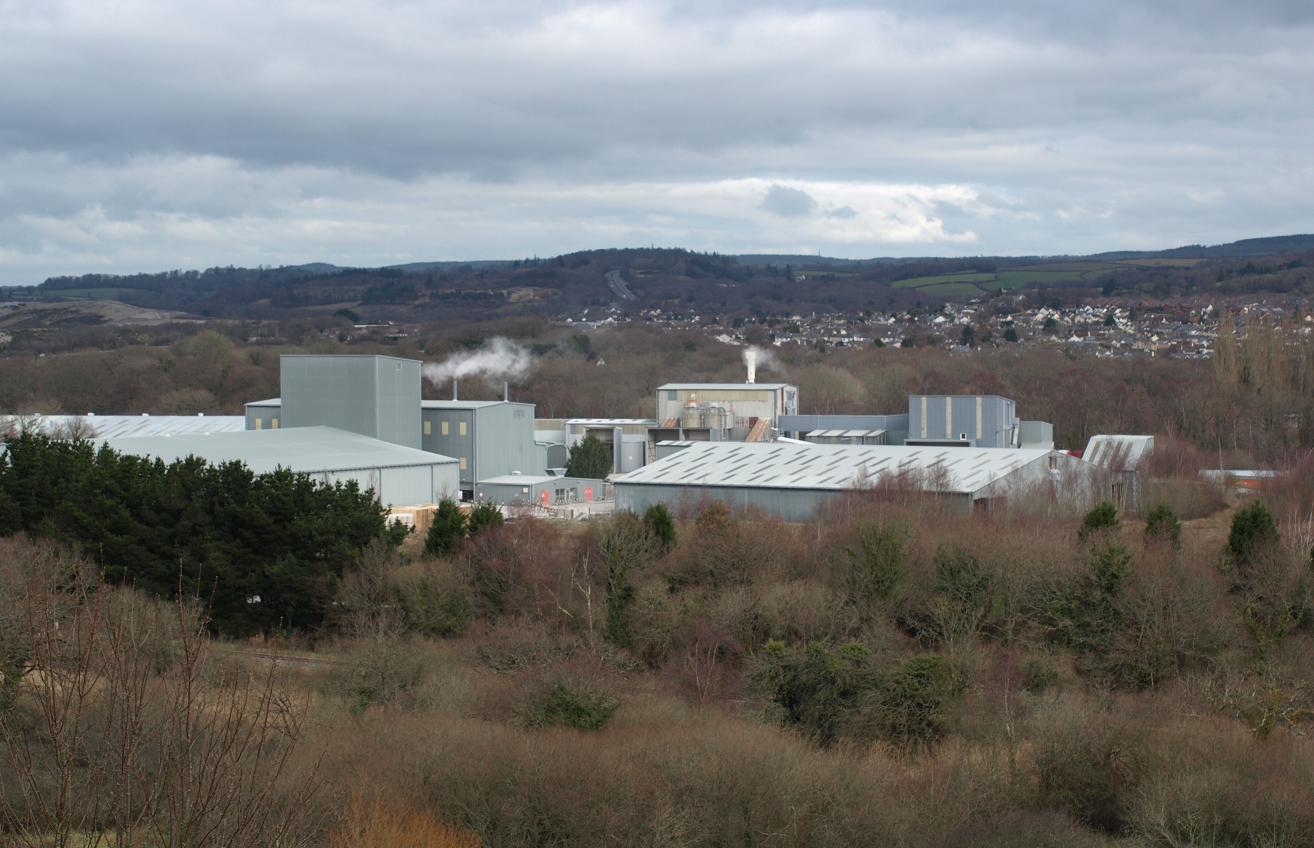

A remaining section of the Newton Abbot to Heathfield line at Teigngrace (March 2012) The ownership of the canal changed again in 1872 when the MSDR was absorbed by the South Devon Railway, which in turn became part of the Great Western Railway following a merger in 1877. Meanwhile the number of barge journeys along the Teign Estuary continued to grow, reaching approximately 2,500 per annum by 1900. But then from the 1920s road transport gradually took over, and the advent of powerful, more reliable diesel-powered lorries in the 1930s led to the canal’s closure in 1939, and it was abandoned. Twelve years later the canal burst its banks, with flood water spilling over into the East Golds clay works.  Sibelco UK’s East Golds clay works from Knowles Hill, with Kingsteignton in the background. (February 2012) To prevent further occurrences, the canal was blocked where the railway bridge crosses it at Jettymarsh and a sluice installed. Since then the channel and all the locks have fallen into disrepair.

Sibelco UK’s East Golds clay works from Knowles Hill, with Kingsteignton in the background. (February 2012) To prevent further occurrences, the canal was blocked where the railway bridge crosses it at Jettymarsh and a sluice installed. Since then the channel and all the locks have fallen into disrepair.  The dry channel of the Stover Canal near the Teign Bridge (March 2012) Local Coal If there had been a local source of coal to fire the kilns, the clay could conceivably have been the basis of a significant pottery industry. In fact, there is a type of coal available in the Bovey Basin, particularly in the northern end towards Heathfield. But is it lignite, a soft brown substance caused by the partial mineralization of vegetable matter, and which can be thought of as half way between coal and peat. Seams of lignite are interspersed with the clay, with the uppermost strata rising to within a foot of the surface. Unfortunately lignite does not burn at a sufficiently high temperature for pottery making, and also tends to give off acrid fumes. According to geologists, when the materials were being deposited to form the Bovey Basin, Dartmoor was 3000 feet high and covered by a sub-tropical forest of huge conifers, similar to giant sequoias. There were vines clinging to the branches and a dense undergrowth of giant ferns, traces of which can be seen in the lignite, along with fir cones and seeds. There are various kinds – some charred, board coal, heavy black coal, highly bituminous, some containing pyrites. The coal seams that were worked here were about 24 feet thick. Within the fissures of the clay and coal, and adhering to the veins of the coal, lumps of bright yellow retinasphalt are found, so saturated with petroleum, that they burn like sealing wax, emitting an agreeable aromatic scent. The lignite was regarded as waste, and as such forms much of the spoil heaps which surround the pits and mines. There used to be a problem with large heaps of lignite catching fire spontaneously, and it is reported that some around Kingsteignton remained alight for many years. Sulpheretted hydrogen was given off when lignite exposed to the air. Attempts were made to bore deeper for better quality pit coal, but this was not successful. The Hackney Canal The Hackney Canal, which opened in 1843 and closed in 1928, was funded by local landowner Lord Clifford to transport ball clay from pits in the Bovey Basin to the Teign. It ran five-eighths of a mile from the Kingsteignton-Newton Abbott road to Hackney quay at the head of the estuary.

The dry channel of the Stover Canal near the Teign Bridge (March 2012) Local Coal If there had been a local source of coal to fire the kilns, the clay could conceivably have been the basis of a significant pottery industry. In fact, there is a type of coal available in the Bovey Basin, particularly in the northern end towards Heathfield. But is it lignite, a soft brown substance caused by the partial mineralization of vegetable matter, and which can be thought of as half way between coal and peat. Seams of lignite are interspersed with the clay, with the uppermost strata rising to within a foot of the surface. Unfortunately lignite does not burn at a sufficiently high temperature for pottery making, and also tends to give off acrid fumes. According to geologists, when the materials were being deposited to form the Bovey Basin, Dartmoor was 3000 feet high and covered by a sub-tropical forest of huge conifers, similar to giant sequoias. There were vines clinging to the branches and a dense undergrowth of giant ferns, traces of which can be seen in the lignite, along with fir cones and seeds. There are various kinds – some charred, board coal, heavy black coal, highly bituminous, some containing pyrites. The coal seams that were worked here were about 24 feet thick. Within the fissures of the clay and coal, and adhering to the veins of the coal, lumps of bright yellow retinasphalt are found, so saturated with petroleum, that they burn like sealing wax, emitting an agreeable aromatic scent. The lignite was regarded as waste, and as such forms much of the spoil heaps which surround the pits and mines. There used to be a problem with large heaps of lignite catching fire spontaneously, and it is reported that some around Kingsteignton remained alight for many years. Sulpheretted hydrogen was given off when lignite exposed to the air. Attempts were made to bore deeper for better quality pit coal, but this was not successful. The Hackney Canal The Hackney Canal, which opened in 1843 and closed in 1928, was funded by local landowner Lord Clifford to transport ball clay from pits in the Bovey Basin to the Teign. It ran five-eighths of a mile from the Kingsteignton-Newton Abbott road to Hackney quay at the head of the estuary.  The site of Hackney Quay (January 2012) The barges used to transport clay along the canals and down the estuary each had a crew of two. The Hackney Canal did not have a towpath, so the barges with their 30 ton loads had to be poled along the canal to the estuary. Once in the estuary a sail (they had characteristic square ‘Viking’ sails) could be raised for the remainder of the journey to Teignmouth, if the wind was favourable. Some journeys had to be made at night if the state of the tide demanded it, which added to the hazards of the job. The work of the lightermen was extremely hard, and they acquired a reputation for toughness and hard drinking. From the turn of the 20th century a steam powered tug was introduced to tow the barges down the estuary to Teignmouth.

The site of Hackney Quay (January 2012) The barges used to transport clay along the canals and down the estuary each had a crew of two. The Hackney Canal did not have a towpath, so the barges with their 30 ton loads had to be poled along the canal to the estuary. Once in the estuary a sail (they had characteristic square ‘Viking’ sails) could be raised for the remainder of the journey to Teignmouth, if the wind was favourable. Some journeys had to be made at night if the state of the tide demanded it, which added to the hazards of the job. The work of the lightermen was extremely hard, and they acquired a reputation for toughness and hard drinking. From the turn of the 20th century a steam powered tug was introduced to tow the barges down the estuary to Teignmouth.  Clay barge and seine fishermen on the Teign. This picture postcard, possibly from around 1900, shows a barge under sail and seine fishermen using nets to catch salmon and the occasional trout. (from the collection of Richard Harris) Finds at Zitherixon

Clay barge and seine fishermen on the Teign. This picture postcard, possibly from around 1900, shows a barge under sail and seine fishermen using nets to catch salmon and the occasional trout. (from the collection of Richard Harris) Finds at Zitherixon  In 1867 workmen digging ball clay in the former Zitherixon quarry found a small wooden effigy buried in mud 25 feet below ground, placed upright against a blackened oak tree stump. The figure came to be known as the Kingsteignton or Zitherixon Idol, and was carved from an oak branch. It is 34cm tall with stubby legs, a long thin body, male genitals, a long neck and large head with either hair or helmet. His neck has a hole drilled through it, possibly to hold detachable arms. Prehistoric wooden figures are very rare in the British Isles, only seven such have been found. A sample of wood taken from the Idol’s head has been carbon dated to between 426 and 352BC, that is the Iron Age or Celtic period. Its purpose is unknown – it could have been a religious idol, an offering to the gods, or even a child’s toy. One expert, Prof Bryony Coles, has said that such figures may have been forerunners of the gods of Norse mythology and may reflect a form of pagan worship once widespread across northern Europe prior to the influence of Roman conquest. (Zitherixon seems to be an alternative name for what is now known as Lower Marsh Quarry, the entrance to which is next to Teign Bridge. This has been proposed as the site of a major new housing development.)

In 1867 workmen digging ball clay in the former Zitherixon quarry found a small wooden effigy buried in mud 25 feet below ground, placed upright against a blackened oak tree stump. The figure came to be known as the Kingsteignton or Zitherixon Idol, and was carved from an oak branch. It is 34cm tall with stubby legs, a long thin body, male genitals, a long neck and large head with either hair or helmet. His neck has a hole drilled through it, possibly to hold detachable arms. Prehistoric wooden figures are very rare in the British Isles, only seven such have been found. A sample of wood taken from the Idol’s head has been carbon dated to between 426 and 352BC, that is the Iron Age or Celtic period. Its purpose is unknown – it could have been a religious idol, an offering to the gods, or even a child’s toy. One expert, Prof Bryony Coles, has said that such figures may have been forerunners of the gods of Norse mythology and may reflect a form of pagan worship once widespread across northern Europe prior to the influence of Roman conquest. (Zitherixon seems to be an alternative name for what is now known as Lower Marsh Quarry, the entrance to which is next to Teign Bridge. This has been proposed as the site of a major new housing development.)  (c) Watts Blake Bearne & Co In 1898, also at the exotically named Zitherixon Quarry, two clay workers removing the material above ball clay deposits about 150m from the present course of the Teign, discovered the substantial remains of a wooden clinker-built vessel. (Clinker building is a method of constructing the hull of a boats by fixing wooden planks to each other so that they overlap along their edges.) Part of what was found was removed from site and presented to Torquay Natural History Museum, where it is still on display. A first attempt to determine the age of the boat using radiocarbon dating was made in 1986, but it wasn’t until 1992 that dendrochronogical tests (which involve matching annual growth ring sequences in a specimen against known reference chronologies from various periods) came up with a likely build date of the first decade of the 14th century. Archaelogists have deduced that it was a working boat designed for river or coastal work, and was about 7m long by about 2•5 m wide and with a draught of about 1m. There have been very few finds of boats of similar size or date; it’s remarkable that the timbers survived underground for so long, and that they were still sufficiently intact after another 100years in a museum to enable accurate growth ring analysis. Kingsteignton Kingsteignton would originally have been a small port on a tidal inlet of the Teign Estuary. It was founded in the early 8th century by the kings of Wessex as the centre of a vast Saxon estate that extended from Teignmouth to Manaton. It gave its name to the Saxon hundred of Teignton. The site had strategic importance because it was at the head of the Teign estuary, potentially blocking incursion by raiders from the sea. But as one of the richest local settlements, it was a target for Danish raiders, who plundered it (along with Bishopsteignton) in 1001 AD. Local historians say that the Domesday entry suggest that in 1066 around forty families were living on the manor, perhaps 200 to 250 people farming about 2000 acres split between a dozen farms. The oldest part, around St Michael’s Church, is situated on a small spur of high ground above the flood plain. However, although Kingsteignton was founded well before the settlements that became Newton Abbot, it didn’t sustain its earlier importance and was overtaken in size and wealth by Newton once land routes became equally important as those on water – in effect Kingsteignton was a land route dead end apart from the ferry to Netherton. Kingsteignton remained the property of the crown until the 13th century. In 1509 the manor passed to the Clifford family, who still hold the honorary title of Lord of the Manor. The family have lived at Ugbrooke House for the last 400 years. The house is located in a valley drained by a small river (the Ugbrook) between Chudleigh and the A380. In the second half of the 18th century the house was remodelled by Robert Adam, and the gardens were landscaped by ‘Capability’ Brown.

(c) Watts Blake Bearne & Co In 1898, also at the exotically named Zitherixon Quarry, two clay workers removing the material above ball clay deposits about 150m from the present course of the Teign, discovered the substantial remains of a wooden clinker-built vessel. (Clinker building is a method of constructing the hull of a boats by fixing wooden planks to each other so that they overlap along their edges.) Part of what was found was removed from site and presented to Torquay Natural History Museum, where it is still on display. A first attempt to determine the age of the boat using radiocarbon dating was made in 1986, but it wasn’t until 1992 that dendrochronogical tests (which involve matching annual growth ring sequences in a specimen against known reference chronologies from various periods) came up with a likely build date of the first decade of the 14th century. Archaelogists have deduced that it was a working boat designed for river or coastal work, and was about 7m long by about 2•5 m wide and with a draught of about 1m. There have been very few finds of boats of similar size or date; it’s remarkable that the timbers survived underground for so long, and that they were still sufficiently intact after another 100years in a museum to enable accurate growth ring analysis. Kingsteignton Kingsteignton would originally have been a small port on a tidal inlet of the Teign Estuary. It was founded in the early 8th century by the kings of Wessex as the centre of a vast Saxon estate that extended from Teignmouth to Manaton. It gave its name to the Saxon hundred of Teignton. The site had strategic importance because it was at the head of the Teign estuary, potentially blocking incursion by raiders from the sea. But as one of the richest local settlements, it was a target for Danish raiders, who plundered it (along with Bishopsteignton) in 1001 AD. Local historians say that the Domesday entry suggest that in 1066 around forty families were living on the manor, perhaps 200 to 250 people farming about 2000 acres split between a dozen farms. The oldest part, around St Michael’s Church, is situated on a small spur of high ground above the flood plain. However, although Kingsteignton was founded well before the settlements that became Newton Abbot, it didn’t sustain its earlier importance and was overtaken in size and wealth by Newton once land routes became equally important as those on water – in effect Kingsteignton was a land route dead end apart from the ferry to Netherton. Kingsteignton remained the property of the crown until the 13th century. In 1509 the manor passed to the Clifford family, who still hold the honorary title of Lord of the Manor. The family have lived at Ugbrooke House for the last 400 years. The house is located in a valley drained by a small river (the Ugbrook) between Chudleigh and the A380. In the second half of the 18th century the house was remodelled by Robert Adam, and the gardens were landscaped by ‘Capability’ Brown.  Ugbrooke House (c) Roger Cornfoot The village would have been well situated for both road and water-borne trade, being close to the long established crossing point of the river at Teign Bridge and on the Roman road from Exeter. It was an established settlement well before Newton Abbot came into being; they are separated by the valley of the River Teign, with the connecting road originally built on a raised causeway.

Ugbrooke House (c) Roger Cornfoot The village would have been well situated for both road and water-borne trade, being close to the long established crossing point of the river at Teign Bridge and on the Roman road from Exeter. It was an established settlement well before Newton Abbot came into being; they are separated by the valley of the River Teign, with the connecting road originally built on a raised causeway.  Kingsteignton Bridge over the Teign, with Jetty Marsh in the foreground and Newton Abbot racecourse and the Teign estuary in the background. (February 2012) In medieval times the village was sufficiently prosperous to fund the rebuilding of the parish church, its 85-foot tower being constructed in the 1480s. Until the mid-19th century it was important locally as the mother church of Highweek and Newton Bushell, and this is reflected in the size and depth of the graveyard, the level of which is well above the adjacent streets.

Kingsteignton Bridge over the Teign, with Jetty Marsh in the foreground and Newton Abbot racecourse and the Teign estuary in the background. (February 2012) In medieval times the village was sufficiently prosperous to fund the rebuilding of the parish church, its 85-foot tower being constructed in the 1480s. Until the mid-19th century it was important locally as the mother church of Highweek and Newton Bushell, and this is reflected in the size and depth of the graveyard, the level of which is well above the adjacent streets.  St Michael’s church (February 2012)

St Michael’s church (February 2012)  Cottages in Church Street with the graveyard wall on the right. (February 2012) The opening of the Hackney Canal in 1843, which encouraged the growth of the ball clay industry, and the arrival of the railway to Newton Abbot a few years later, fuelled the development of Kingsteignton in the 19th century. Many labourer’s cottages were built, changing it from a quiet rural settlement to a large and busy semi−industrial village.

Cottages in Church Street with the graveyard wall on the right. (February 2012) The opening of the Hackney Canal in 1843, which encouraged the growth of the ball clay industry, and the arrival of the railway to Newton Abbot a few years later, fuelled the development of Kingsteignton in the 19th century. Many labourer’s cottages were built, changing it from a quiet rural settlement to a large and busy semi−industrial village.  Workers cottages in Sandpath Road. (February 2012) One of the features of the town centre area is the Fairwater Leat, seen here at the junction of Fore Street and Crossley Moor Road. (February 2012)

Workers cottages in Sandpath Road. (February 2012) One of the features of the town centre area is the Fairwater Leat, seen here at the junction of Fore Street and Crossley Moor Road. (February 2012) It is fed by springs at Rydon, a few hundred metres to the north, and was constructed in the late 13th or early 14th century to power two mills, one in Crossley Moor Road and the one pictured below, situated next to the church. As it is now it doesn’t look powerful enough to power a mill – perhaps its flow was managed differently when it was in use.

It is fed by springs at Rydon, a few hundred metres to the north, and was constructed in the late 13th or early 14th century to power two mills, one in Crossley Moor Road and the one pictured below, situated next to the church. As it is now it doesn’t look powerful enough to power a mill – perhaps its flow was managed differently when it was in use.  Lower Mill House and mill building, now converted to residential use. (February 2012) In 1850, before its first period of rapid growth, Kingsteignton’s population was 1,500. It is now about 13,000, the settlement having spread over a mile northwards from its original centre. It was officially a village (albeit rather overgrown) until 1st January 2009, when it formally became a town. To a modern day visitor the town appears to be a real mish-mash, with houses of different styles and ages mixed in with commercial and industrial premises, even in the historic central area. For example, the untidy yard shown below is off Church Street, right next to the attractive lych gate at the entrance to St Michael’s church. (February 2012)

Lower Mill House and mill building, now converted to residential use. (February 2012) In 1850, before its first period of rapid growth, Kingsteignton’s population was 1,500. It is now about 13,000, the settlement having spread over a mile northwards from its original centre. It was officially a village (albeit rather overgrown) until 1st January 2009, when it formally became a town. To a modern day visitor the town appears to be a real mish-mash, with houses of different styles and ages mixed in with commercial and industrial premises, even in the historic central area. For example, the untidy yard shown below is off Church Street, right next to the attractive lych gate at the entrance to St Michael’s church. (February 2012)  St Michael’s church framed by decorative woodwork on the lych gate at the entrance. (February 2012)

St Michael’s church framed by decorative woodwork on the lych gate at the entrance. (February 2012)

A detail of (much weathered) wrought iron work in the lych gate (February 2012)

A detail of (much weathered) wrought iron work in the lych gate (February 2012)  Nos 49 and 51 Fore Street, at the eastern end of what was once the main street of the village. They were built as a single house around the late 15th century but, apart from the massive chimney, which was probably once embedded in the now missing adjoining property, there is little externally to indicate their age. The building has Grade II Listing status, and the register entry says it was originally just three rooms open to the roof, with floors inserted later to create first floor rooms during the 16th and 17th centuries – although the central hall is still full height. This building would have been in place when Kingsteignton was just a small village clustered around the church. The picture below, with a distant view of Kingsteignton from the opposite side of the Teign estuary, illustrates what the village and its environs would have looked like before its period of rapid expansion.

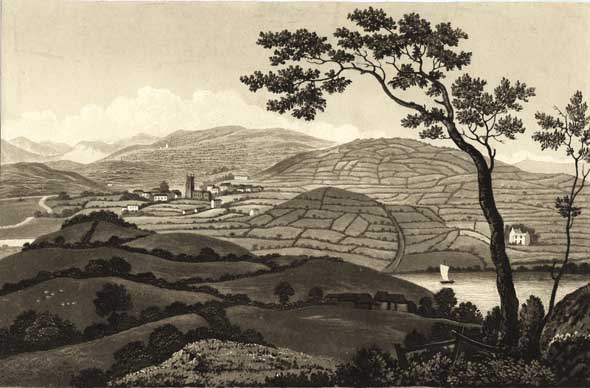

Nos 49 and 51 Fore Street, at the eastern end of what was once the main street of the village. They were built as a single house around the late 15th century but, apart from the massive chimney, which was probably once embedded in the now missing adjoining property, there is little externally to indicate their age. The building has Grade II Listing status, and the register entry says it was originally just three rooms open to the roof, with floors inserted later to create first floor rooms during the 16th and 17th centuries – although the central hall is still full height. This building would have been in place when Kingsteignton was just a small village clustered around the church. The picture below, with a distant view of Kingsteignton from the opposite side of the Teign estuary, illustrates what the village and its environs would have looked like before its period of rapid expansion.  (from www.devon.gov.uk) It is evident that some artistic licence has been taken with the hills in both the background and foreground. The photo below was taken (in December 2013) from the Netherton road, somewhere near the artist’s point of view. It shows modern-day housing at Kingsteignton bordered by the A380 dual-carriageway, the Passage House Hotel on the far side of the Teign, and the sewage works and buildings of Buckland Barton on this side. On a larger version of the photo, the church tower can be seen on the extreme left.

(from www.devon.gov.uk) It is evident that some artistic licence has been taken with the hills in both the background and foreground. The photo below was taken (in December 2013) from the Netherton road, somewhere near the artist’s point of view. It shows modern-day housing at Kingsteignton bordered by the A380 dual-carriageway, the Passage House Hotel on the far side of the Teign, and the sewage works and buildings of Buckland Barton on this side. On a larger version of the photo, the church tower can be seen on the extreme left.